v die bending chart|what is v die formula : factory Lower Die (Matrix or V-die): The bottom portion that supports the material and provides the forming cavity. Guide Rails: Ensure proper alignment and positioning of the dies during operation. Lower Die Base: Provides a .

17 de out. de 2023 · No deposit offer terms: https://www.888casino.dk/promotions/no-deposit-bonus. Get the best online casino app and enjoy a wide selection of Live Casino .

{plog:ftitle_list}

Resultado da Liverpool x Manchester United - Campeonato Inglês - Minuto a Minuto Terra. Ir ao conteúdo; Página principal Notícias da copa. Produtos. E-mail. PUBLICIDADE. Esportes. 0. Destaques. 1.

Use this Air Bending Force Chart to help you select the correct V opening in your die to get the bend that you want and ensure your tool selection is safe.NOTE: The chart above is based on mild steel (tensile strength of 60,000 PSI) .Considering material thickness (t) and die opening (V) the table below shows the most important bending data: Minimum bendable flange length bmin; Bending radius ir on the sheet metal; Press force F in KN / m How to Select a V-Die Opening for Press Brake Bending. There is not only one correct V opening for a certain material or thickness. There are ideal V openings for different .

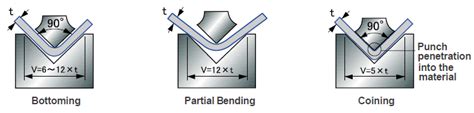

Air forming and V-die selection. Air forming, bottom bending, and coining are metal forming methods. Air forming, the most common, is a three-point operation. The actual inside .

Lower Die (Matrix or V-die): The bottom portion that supports the material and provides the forming cavity. Guide Rails: Ensure proper alignment and positioning of the dies during operation. Lower Die Base: Provides a . Through this bending force chart, you can easily determine the minimum bending pressure, minimum flange length, and bending radius corresponding to different V openings when bending mild steel and stainless .Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, .

NOTE: The chart above is based on mild steel (tensile strength of 60,000 PSI) formed to an included angle of 88°. See chart to the right for other materials. Forming to other angles will .

Approximate pressure in tons per linear foot required to make 90 degree air bend in mild steel. Shaded figures represent ideal conditions for light angle bending; punch with radius . If the die width is acceptable, calculate the bend radius using the 20 percent rule. Start with the median value. Back to our 304 stainless example, the median percentage is 21. Multiply this percentage by the actual die .This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange. You just have to insert the characteristics of the sheet metal to be bent. The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel, and Weldox® or Strenx® high-strength steels. Based on this example—in which the minimum radius is 0.046—if 1/32 in. (.032) were used in the calculations, the bend deductions then, obviously, would be incorrect. Calculating Inside Radius Based on V-die Opening. .

AIR BENDING FORCE CHART IMPERIAL TONNAGE • IMPERIAL V-OPENINGS T IR V MF STANDARD FORMULAS FOR SELECTING A V-OPENING Material Thickness:.105" or Less = T x 6 .120" – .313" = T x 8 .375" – .500" = T x 10 .625" & Thicker = T x 12 NOTE: Formulas and chart are for reference only. T = Material Thickness; V = V-Opening; MF = Minimum Flange . Most important, if you know the math, you know exactly what goes into each bend. Charts and rules of thumb are useful, but in precision metal fabrication, you should, well, . (575 × Material thickness squared)/ V die width]/12 × Material factors × Bending method factors = Tonnage per inch. In this calculation, air forming mild steel is the . Several basic types of bending methods can be incorporated into a stamping operation—wipe bending, V bending, and rotary bending. All three are popular, and each has its advantages and disadvantages. . Part IV and Part V cover common stamping die components. Part VI explains specialty die components. Part VII provides an overview of metals .Air Bending is a common practice in the bending industry. An Air Bending Force Chart will help you select the correct V opening in your die to get the bend that you want. It will also ensure your tool selection is safe. Watch now to learn how to air bend right.

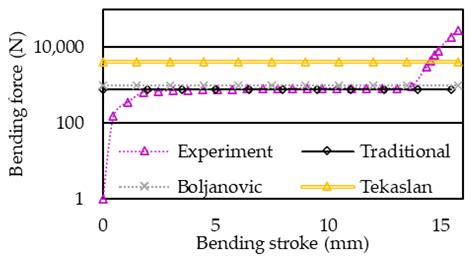

The Air Bend Force Chart. When air bending, you can refer to a tonnage or force chart, usually with a material gauge on the vertical axis and V-die width on the horizontal axis. Note that the forming force values in these charts are based on specific die width-to-material-thickness ratios (or die ratios), such as the following, with material .

what is v die formula

v die width formula

V-Series Black Dies make it much easier to produce small flanges, small bend radii, and bends closer to holes. Replaceable inserts decrease friction and enable better performance on certain tough-to-bend applications. Download this flyer for more product details, minimum angles, maximum tonnage and best practices related to V-Series Black (VSB .

Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, and the ultimate tensile strength of the material.

The bend allowance for 3.0 stainless steel with V25 die is 6; The bend allowance for 3.0 stainless steel with V20 die is 5.5; (The copper bars exceeding 6mm all use the bending allowance of V40 lower die) A well-maintained bend allowance chart is a vital tool in the sheet metal fabrication industry.

An Air Bend Force Chart, or Force Chart breaks down a number of key components of sheet metal bending in an easy to reference format. Being able to read a bend force chart is crucial for any Brake Press operator and sheet metal engineer. The gauge, inside radius, die opening, and minimum flange length are all interconnected through different equations and relationships, the .

Resulting bend has inside radius approximately equal to metal thickness. If stock exceeds 1/2 inch in thickness, it is good practice to increase die’s opening to at least 10 times the metal thickness. Bending pressures required for other metals as compared to 60,000 P.S.I. tensile mild steel on chart. Soft Brass 50% of pressure listed Soft . When air bending mild steel, the inside bend radius forms at approximately 16 percent of the V-die opening. So if you air-bend material over a 1-in. V die, your inside bend radius will be about 0.16 in. Say a print specifies 0.125-in. material. In a perfect world, you’d multiply that thickness by 8 and use a 1-in. V die. Simple enough.Although some fabricators are used to relating the internal radius of the part with the punch radius, this is not always how bending works. Most of the times the iR is a result of the V opening used.. On most parts we bend, the ideal iR = 1 . So, the larger the V opening, the larger the minimum leg or flange we must have on a profile. There is a geometrical formula to determine this minimum length for a leg. Define b as the internal minimal leg length, V as the .

ties. Staged bending will make small runs cost-effective by simplifying complex bending sequences and handling each part only once. Our punches are categorized into four levels, depending on their operating height. H70mm, H90mm, H120mm and H160mm. Our staged dies are offering stage bending in combination with acute bending, hemming and offset . In air bending, the opening width V of the lower die is typically chosen to be 8 to 10 times the thickness of the sheet, S. Press brake manufacturers often list the corresponding values of the die width, V, and the inner diameter, r, of the bending workpiece on their bending force parameter table. As a general rule, r=(0.16~0.17)V

Air Bending Calculator. Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, bend length, material and a safety factor. 4. Four-corner Bending Mold . Four-corner bending parts can be formed in one or two steps.. 1) The structure of the simple one-step four-corner bending mold is shown in Figure 2-28. When bending parts with this mold structure, there often arises inaccuracies in the external corner shape and thinning of the straight-wall sections (especially when the material thickness .Press Brake Tonnage Chart Approximate pressure in Tons per Linear Foot Required to Make 90 degreeAir Bend on Mild Steel (without fully bottoming the top die into the bottom die). Highlighted Figures are the pressures required using a punch with a radius equal to the metal thickness and die opening approximately 8X metal thickness.

vol.2 about v - bending type. vol.3 preparation for bending 1 (tonnage chart , minimum flange length, v width selection) vol.4 preparation for bending 2 (punch marking example, v - bending force calculation formula) vol.5 the features of bending (bending allowance, spring - back) vol.6 about tool selectionIt is very common for press brake operators to have their own personal “rule of thumb” when choosing the V opening for a certain job application. Although these rules may have developed over time from their personal experience, they do not take into account how commercial sheet metals actually behave and can sometimes lead to imperfect final pieces.PRESS BRAKE BENDING CHART. Tons required per foot to bend. mild steel having max 72,000. PSI tensile strength and max. 40,000 PSI yield strength. The tonnages indicated in black. boxes are for di e openings 8. times thickness rof metal up 1/4” and 10 times thickness of metal. recommended above 1/4” in. orange boxes. The inside radius of a .

Learn how to determine the optimal V-Die opening or Die Size for sheet metal air bending. Skip to final Equation: [4:50]Believe it or not, there is a scien. You'll find detailed charts and explanations for different punches and dies, ensuring you select the right tools for your metal bending needs. Learn how to optimize your press brake performance and achieve precise bends with confidence. . 88°, 90°, 60°, 30° punch, round, hemming and Z punch; 1V, 2V, multi-V die as well as combined die .

When air bending mild steel, the inside bend radius forms at approximately 16 per cent of the V-die opening. So if you air-bend material over a 1-in. V die, your inside bend radius will be about 0.16 in. Say a print specifies 0.125-in. material. In a perfect world, you’d multiply that thickness by 8 and use a 1-in. V die. Simple enough.

press brake bending v die

how to calculate v die

Resultado da Fórum. 23/08/2023 18:22. 1447. RobertoPires. puts. 6 dias após o jogo a imprensa ainda discutindo se foi mão no gol do Lucas, estão pressionando .

v die bending chart|what is v die formula